The Future of UV Lining Rehabilitation

Explore the United Felts UV CIPP Portfolio

CONTACT OUR EXPERTS Ready to Learn More About UV CIPP?

Revolutionizing Infrastructure with UV-Cure Technology

United Felts proudly offers the most robust UV CIPP liner portfolio in the market. Featuring our advanced United GRP and the proven patent-pending EnviroCure UV®, we deliver unmatched strength, flexibility, and environmental sustainability tailored for diverse infrastructure needs.

PRODUCT FEATURES United Felts UV CIPP Portfolio

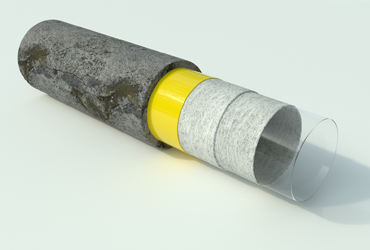

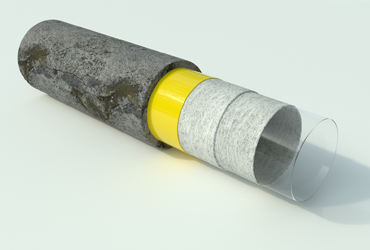

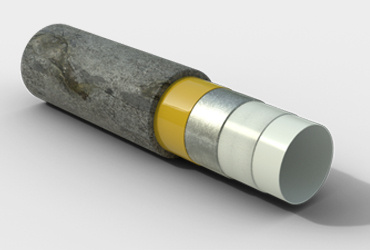

United UV GRP

Strength for the Long Haul

- Multi-layer, overlapping continuous glass fiber liner

- Pre-impregnated and installation-ready up to 2,000 ft I 610m*

- Optimized for long, straight sections and large diameters

- Made in America, made on-demand, and delivered in as little as two weeks

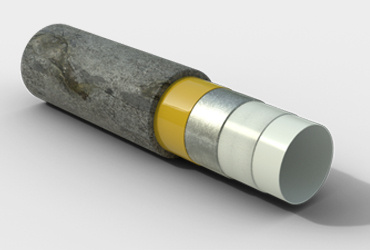

EnviroCure UV®

Patent Pending

Flexibility Meets Innovation

- Dimples at lateral connections for easy reinstatement

- Ideal for sections and multiple laterals

- Thinner wall design for enhanced flow capacity

- Sustainable, reducing environmental impact during installation

Training & Support

United Felts' UV liners are backed by our promise of quality and our unparalleled commitment to meeting the unique requirements of our customers. Training, consultation and field support are available for experienced pros, and those new to UV cure technologies.

United UV GRP

Strength for the Long Haul

- Multi-layer, overlapping continuous glass fiber liner

- Pre-impregnated and installation-ready up to 2,000 ft I 610m*

- Optimized for long, straight sections and large diameters

- Made in America, made on-demand, and delivered in as little as two weeks

EnviroCure UV®

Patent Pending

Flexibility Meets Innovation

- Dimples at lateral connections for easy reinstatement

- Ideal for sections and multiple laterals

- Thinner wall design for enhanced flow capacity

- Sustainable, reducing environmental impact during installation

Training & Support

United Felts' UV liners are backed by our promise of quality and our unparalleled commitment to meeting the unique requirements of our customers. Training, consultation and field support are available for experienced pros, and those new to UV cure technologies.

COMPARISON CHART Choose the Right UV Liner for Your Project

Compare performance and installation benefits of Envirocure UV and UV GRP liners to match your project needs. Both options are impregnated and ready for quick deployment, in as little as two weeks from any of our strategically located wet-out facilities throughout the United States.

| ENVIROCURE UV® PATENT PENDING |

UNITED UV GRP | |

| PRODUCT FEATURES | ||

| Dimples at Lateral | Yes — Allowing for fast easy reinstatement | No |

| Diameter Range | 6"-36" | 6"-72" |

| Typical Applications | Sections containing multiple laterals | Long, straight sections, minimal lateral connections, larger diameters |

| ASTM TESTS | ||

| D790 Flex Strength | 20,000 psi | 35,000 psi |

| D790 Flex Modulus | 1,500,000 psa | 2,000,000 psi |

| D648 Heat Distortion Temp | 248°F @ 264 psi | 248°F @ 264 psi |

| MATERIAL SPECS | ||

| Reinforcement Material | Stitched, Multiaxial ECR Glass | Stitched, Multiaxial ECR Glass |

| Glass Fiber Content Per ISO 1172 | 50% (+/-5%) | 50% (+/-5%) |

| Glass Weight Per Unit | 1112 g/m² (+/- 10%) | 850-900 gsm/m² (+/- 10%) |

EnviroCure UV: A Specialty CIPP System

EnviroCure UV is delivered to the jobsite pre-impregnated with resin and ready for installation. This feature, combined with a faster and more efficient UV curing process, leads to improved QA/QC, lower job costs, smaller equipment footprint and reduced CO2 emissions during installation.

MORE THAN JUST LINER

United Felts, Now Part of Vortex, Delivers a Liner Package

With the most robust offering in the market, Vortex and United Felts deliver a complete solution to help you enter the UV market successfully, including liners and equipment.

Get in touch to talk to our experts about our equipment line and learn which option is right for you. We have your UV solution, and the training and support to back it up!

Equipment Portfolio

SEWER REHAB NEAR MASS GENERAL HOSPITAL

Pipe Relining Eliminates Need To Dig Up Old Brick Sewer Near Hospital’s Entrance

Problem: Deteriorated and leaking brick sewer interceptor serving Massachusetts General Hospital and located in front of the ER entrance.

Solution: Quadex Lining System® (QLS) GeoKrete® was applied in areas where CIPP could not be performed due to headwalls and other obstructions. The versatile application options of QLS/GeoKrete allow the non-round sections of the interceptor to be fully restored when there was no other viable option. Traditional CIPP was installed in rounded sections of interceptor.

Read The Case Study